Explore Waterproof & Weatherproof NEMA-Rated Outdoor Enclosures and Cabinets with AZE!

-

Durable Materials: Choose from galvanized steel, stainless steel, or aluminum for superior corrosion resistance and longevity.

-

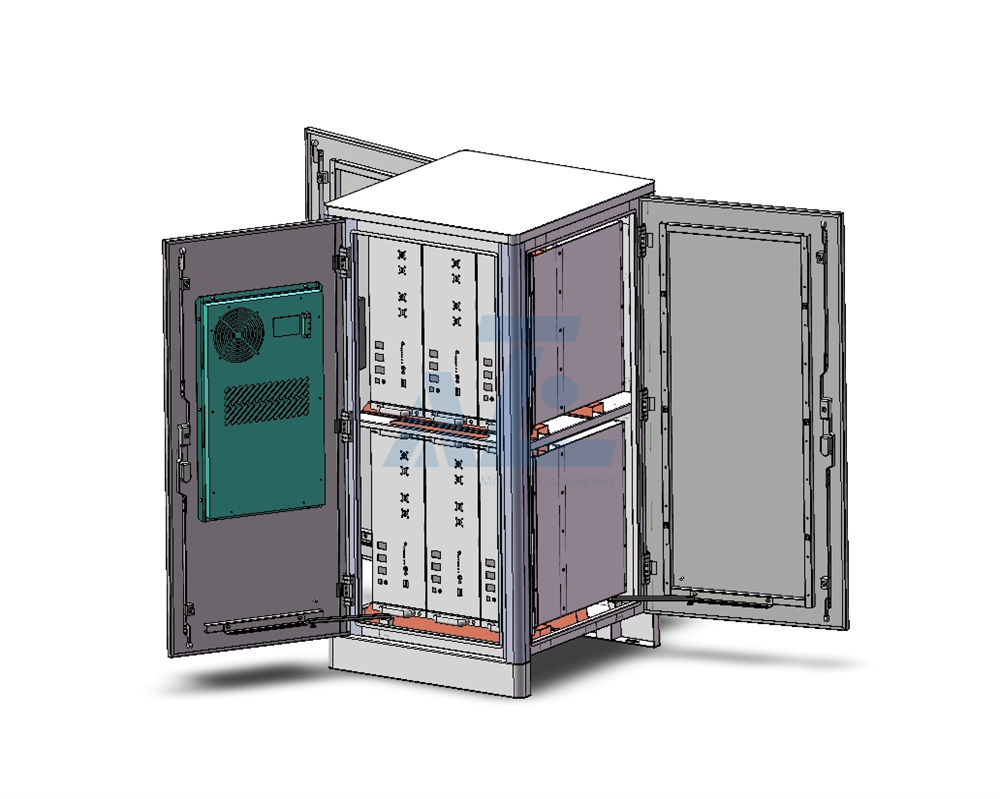

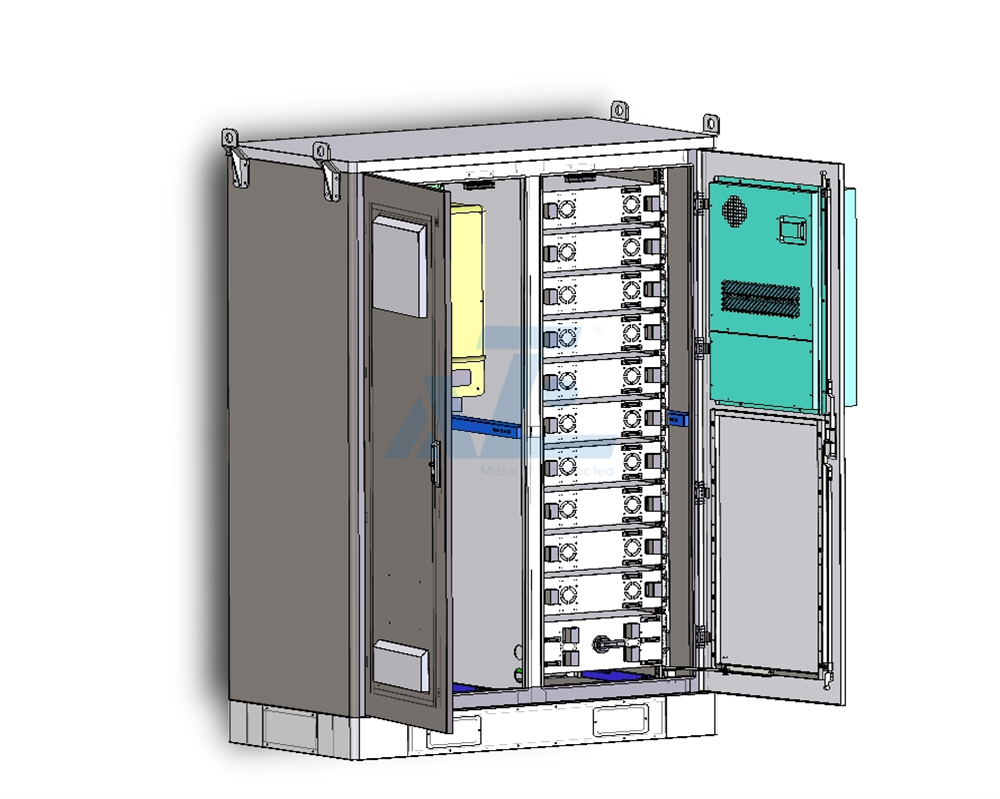

Robust Ratings: Available in IP55, IP65, NEMA 3R, NEMA 4, and NEMA 4X ratings, perfect for outdoor electrical, telecom, and battery cabinet applications.

-

Climate Control Solutions: Customize with fans, air conditioners, TEC (thermoelectric coolers), or heat exchangers to maintain optimal operating conditions.

Protect your equipment in any environment with AZE's high-performance enclosures. Contact us today to find the perfect solution for your needs!

Overview

AZE Outdoor Enclosures: Superior Protection for Your Electrical and Electronic Equipment

When it comes to safeguarding your electrical and electronic systems in demanding outdoor environments, AZE Outdoor Enclosures are the ultimate solution. Designed to meet the highest industry standards, our enclosures provide unmatched durability, weatherproofing, and reliability for a wide range of applications.

Key Features of AZE Outdoor Enclosures

Outdoor Enclosures are specially design for enclosure requirements in outdoor installations,they are made of galvanized steel,stainless Steel or other materials are on request.This range of outdoor enclosures consist of wall mounting enclosures, pole mounting enclosures and pad mount enclosures.

-

Weatherproof Design: Built to withstand harsh outdoor conditions, our enclosures are engineered to resist rain, snow, dust, and extreme temperatures, ensuring your equipment remains protected year-round.

-

NEMA-Rated Performance: AZE enclosures are available in various NEMA ratings (such as NEMA 3R, NEMA 4, and NEMA 4X), making them ideal for environments where corrosion, moisture, and debris are a concern.

-

Durable Construction: Made from high-quality materials like stainless steel, aluminum, and polycarbonate, our enclosures offer exceptional strength and longevity, even in the most challenging industrial settings.

-

Customizable Solutions: Whether you need standard outdoor electrical cabinets or custom-designed enclosures, AZE provides tailored solutions to meet your specific requirements.

-

Easy Installation and Maintenance: Designed with user convenience in mind, our enclosures feature accessible designs for hassle-free installation and maintenance.

AZE is a leading, high-quality IP rated or NEMA type weatherproof electrical enclosures, all-in-one ESS solution, solar energy and lithium battery cabinet manufacturer in China,we provide wall mounted, pole mounted or floor-standing electrical enclosures,telecom cabinets, battery storage rack enclosures up to IP66 or NEMA 4/4X type. Our offerings include powder-coated galvanized steel, stainless steel, and marine-grade aluminium outdoor telecom, electrical or ESS battery storage enclosures.

We supply outdoor electrical enclosures and electrical cabinets for low-voltage switchgear and controlgear assemblies. They are are manufactured to the highest standards using world-class international manufacturing facilities. We have provided thousands of electrical enclosures throughout Australia, Europe, UK, USA, Dubai UAE, New Zealand and Asia Pacific regions.

Identical to the infrastructure needs of a traditional, indoor data cabinet, a NEMA-rated environmental solution should address environmental conditions, airflow, cable management/connectivity, power and security requirements, you can choose from floor standing or wall mount style based on your environment,all of our outdoor server racks are built to protect your expensive network equipment from exposure to the environment such as dust or water.

Our outdoor telecom cabinets are designed to protect your sensitive network equipment from harsh environments where equipment may be exposed to dust or water. For added protection, there is a water and dust proof polyurethane door joint strip. The cooling options can be fan units, heat exchanger, AC/DC air conditioners that provided to cool down your IT equipments that installed inside the cabinets.

We offer a comprehensive range of outdoor enclosures for virtually any installation. Designed to NEMA Type 3R, NEMA Type 4 requirements, AZE's cabinets and enclosures protect equipment from harsh environmental conditions. Because our enclosures have a similar yet flexible design layout, installation is fast, with configuration changes easily made when a network demands change.

NEMA Rating Basics

The National Electrical Manufacturers Association issues its NEMA rating system to help enclosure buyers easily evaluate an enclosure’s performance specs. The ratings are designed to categorize an enclosure based on its resistance to common environmental hazards, including:

- Airborne dust and debris

- Weather conditions such as rain, snow, and sleet

- Splashing, dripping, and hose-directed water

- Submersion in water

- Corrosion

NEMA 4 Outdoor Enclosures vs. NEMA 4X Outdoor Enclosures

NEMA 4 outdoor enclosures and NEMA 4X outdoor enclosures are both popular across many different industries. Both ratings indicate a waterproof and dust-tight enclosure that provides excellent protection against airborne particulates, adverse weather conditions, and repeated hose-downs.

However, a NEMA 4X outdoor enclosure has an additional feature that a NEMA 4 outdoor enclosure lacks: protection from corrosion. Corrosion can be a big problem in many different enclosure applications, and a NEMA 4X outdoor enclosure can help protect your devices.

AZE can also provide customize products or projects based on requirements,choose from a broad range of models, configurations, mounting options, sizes, finishes and type ratings.

We offer a variety of IP rated or NEMA standard outdoor enclosures for telecommunications equipment. If one of our standard products doesn't quite meet your application requirements, we can modify the design to create the ideal outdoor product for your needs and also can create new products built to your specifications. Before you purchase any telecommunications cabinet, consider the following:

NEMA Ratings for Outdoor Enclosures

Finding outdoor enclosures that meet all of your application requirements is made simpler through NEMA ratings. Cabinets with a 3, 3R, 3S, 3X, 3RX, 3SX, 4, 4X NEMA standard are all properly made to withstand the outdoor elements to varying degrees. The key is to select the enclosure rating that best meets your environmental needs, and then find an appropriate enclosure with that rating. AZE manufactures metal cabinets and enclosures that meet or are designed to NEMA type 3R, 4

NEMA Rated Outdoor Enclosures External Features

Also, keep in mind that if you are going to connect external features, such as a cable or antenna, it may be necessary to modify your enclosure for the outdoors. Every cutout you add to the cabinet provides an opportunity for water or other contaminants to seep in. Using the right accessories, such as cable glands, can help seal out dust, dirt, and damaging liquids.

NEMA Rated Outdoor Cabinets Environmental Factors

Additionally, to ensure the performance and reliability of your equipment and to give it the best chance at a long lifespan, you must consider outdoor environmental factors. These factors include variations in the internal operating temperature with temperature extremes, water, and dust ingress at cabling connections. Other dynamic factors include moisture, condensation, chemicals, and corrosive gases that can affect internal component and material selection. Don't forget about the panel layout and design and the need for environmental conditioning (cooling and heating).

Climate Control Options for NEMA Rated Outdoor Telecom Cabinet

For electronics to survive in an outdoor enclosure, they typically require climate control.We can offer AC or DC powered air conditioner, heat exchangers or TEC. Whether you're keeping your electronic systems and components cool in the summer or warm in the winter, outfitting your outdoor enclosures with the appropriate heating and cooling features will help protect your investment.

Explore top-of-the-line outdoor industrial enclosures and telecom cabinets with advanced design features – industry-leading products setting the standard for excellence.

One of the biggest challenges of terminating your telecom equipment outdoor is finding outdoor enclosures that will be able to properly withstand the elements. Temperature, moisture, ice, shock hazards, and UV damage are all potential dangers to consider before purchasing an outdoor enclosure or cabinet. On top of all that, network hardware generates excess heat on its own, meaning you might need to consider a temperature solution that manages airflow with cooling technology. Contact us now when you need an outdoor enclosure, AZE will work with you to select or design an outdoor electronics enclosure that meets your unique application's requirements.

AZE is ready to meet project needs, whether small or large scale.Explore our cutting-edge products developed through extensive research. Browse our diverse portfolio including Electrical, Data, Infrastructure, Hygienic, Machine, and Thermal Management solutions today. We look forward to working with you to meet your electrical enclosure needs.

Store, Protect and Cool Your IT Equipment OUTDOOR - Extremely Harsh Weather

AZE is proud to offer an extensive line of outdoor communication enclosures, outdoor server cabinets, outdoor network rack, data,telecom, electrical, industrial waterproof enclosures and outdoor battery,solar engery storage cabinets. We provide a large variety of standard sized or customized models and can accommodate any customized projects. Built AZE Tough, for the telecommunication, aerospace and industrial market space our NEMA 3R to 4X enclosures are designed to handle harsh environments and extreme weather climates. From the unforgiving dry heat in warmest areas to high elevation cold, wet terrains, AZE's NEMA rated outdoor enclosures and NEMA rated Cabinets thrive.

Why Choose AZE Outdoor Enclosures?

Deploying IT infrastructure in remote locations with uncertain access and edge computing power management, AZE designs a wide range of outdoor enclosure for harsh environments and extreme weather, from IP55 to IP65, NEMA 3R to NEMA 4X, which not only protect your vital electronic equipment from vandalism and environmental damage, but it also ensures it runs in optimal conditions for peak performance levels.

-

Reliability: Trusted by professionals across industries, AZE enclosures deliver consistent performance in even the toughest environments.

-

Compliance: Our products meet or exceed industry standards, ensuring safety and compliance with regulatory requirements.

-

Innovation: AZE is committed to continuous improvement, incorporating the latest advancements in materials and design to provide cutting-edge solutions.

Whether you're looking for weatherproof enclosures, NEMA-rated cabinets, or custom outdoor solutions, AZE has the expertise and product range to meet your needs. Protect your investments and ensure uninterrupted operations with AZE Outdoor Enclosures—your partner in durability and performance.

Application

AZE Outdoor Enclosures | Weatherproof NEMA-Rated Enclosures for Telecom, 5G, Oil & Gas, and More

AZE Outdoor Enclosures are versatile and suitable for a wide range of industries and applications, including:

-

Industrial Equipment Protection: Safeguard control panels, transformers, and other critical equipment in manufacturing plants and factories.

-

Telecommunications: Protect sensitive communication systems and networking equipment in outdoor installations.

-

Renewable Energy: Ensure the reliability of solar inverters, wind turbine controls, and other renewable energy systems.

-

Transportation and Infrastructure: Provide robust protection for traffic control systems, railway signaling, and roadside electrical installations.

-

Commercial and Residential Use: Ideal for outdoor lighting controls, security systems, and HVAC equipment.

A manufacturer of standard and custom NEMA enclosures and cabinets, AZE offers solutions in 3R through 4X, for telecommunication, aerospace, and industrial applications. AZE Outdoor Enclosures can be applied across various industries, including Telecommunications, Manufacturing, Public Utilities, Oil & Gas, and Government Operations. Each application is tailored to highlight the specific needs and benefits of using AZE enclosures in these sectors.

1. Telecommunications

AZE Outdoor Enclosures are essential for protecting critical telecommunications infrastructure, ensuring reliable connectivity and performance in outdoor environments.

Wireless/Broadband

-

Application: Housing wireless transmitters, receivers, and broadband equipment.

-

Benefits: AZE enclosures provide weatherproof protection and thermal management to ensure uninterrupted signal transmission, even in extreme weather conditions.

Fiber Optics

-

Application: Protecting fiber optic splice closures, distribution panels, and termination points.

-

Benefits: Our enclosures safeguard delicate fiber optic components from moisture, dust, and physical damage, maintaining signal integrity and reducing downtime.

Back Haul

-

Application: Securing backhaul equipment that connects cell towers to the core network.

-

Benefits: AZE enclosures offer NEMA-rated durability and corrosion resistance, ideal for remote or harsh environments where backhaul systems are often deployed.

Base Station

-

Application: Enclosing base station electronics, including power supplies, routers, and cooling systems.

-

Benefits: Designed for outdoor durability, our enclosures ensure reliable operation of base stations, supporting seamless communication networks.

5G Infrastructure

-

Application: Protecting 5G small cells, antennas, and edge computing devices.

-

Benefits: AZE enclosures are built to handle the high heat output and environmental challenges of 5G equipment, ensuring optimal performance and longevity.

2. Manufacturing

In manufacturing facilities, AZE Outdoor Enclosures protect sensitive equipment from harsh industrial environments.

-

Application: Housing control panels, PLCs (Programmable Logic Controllers), and motor drives.

-

Benefits: Our enclosures provide dust-tight and waterproof protection, ensuring the reliability of automation systems and reducing maintenance costs.

3. HVAC (Heating, Ventilation, and Air Conditioning)

AZE enclosures are ideal for protecting HVAC systems installed outdoors or in challenging environments.

-

Application: Enclosing HVAC controls, compressors, and sensors.

-

Benefits: With weatherproof and corrosion-resistant designs, AZE enclosures extend the lifespan of HVAC components and ensure efficient operation in all climates.

4. Public Utilities

Public utility systems require robust protection to maintain service reliability and safety.

-

Application: Protecting electrical distribution panels, metering systems, and SCADA (Supervisory Control and Data Acquisition) equipment.

-

Benefits: AZE enclosures offer NEMA-rated protection against moisture, vandalism, and extreme temperatures, ensuring uninterrupted utility services.

5. Oil & Gas

In the oil and gas industry, equipment must withstand some of the harshest conditions on Earth.

-

Application: Enclosing wellhead controls, pipeline monitoring systems, and explosion-proof equipment.

-

Benefits: AZE enclosures are built to handle corrosive environments, high pressures, and flammable conditions, ensuring safety and reliability in critical operations.

6. Government Operations

Government facilities and infrastructure demand secure and durable solutions for outdoor equipment protection.

-

Application: Protecting traffic control systems, surveillance cameras, and emergency communication systems.

-

Benefits: AZE enclosures provide tamper-resistant and weatherproof designs, ensuring the security and functionality of government operations in all conditions.

As the manufacturer of standard and custom NEMA enclosures and cabinets, AZE offers offer an extensive line of outdoor communication enclosures in 3R through 4X, for telecommunication, aerospace, and industrial applications. Our NEMA 3R to 4X enclosures are designed to handle harsh environments and extreme weather climates.

Options

Consider the environmental conditions of where equipment will be deployed. A specific NEMA rating, combined with BOX components, will address these considerations and work together to create a safe environment, free of dust, dirt, precipitation, etc.

Ambient Conditions

- Intense sun

- Fluctuating temperatures

- Precipitation

- Ice formation

- Ingress of foreign objects (dust, flyings, etc.)

Equipment specifications from the manufacturer

- Operating temperature

- Connectivity standards

- Power requirements

- Physical space clearance and requirements

Airflow Options

Our outdoor enclosures are configured with airflow solutions appropriate for the size of the cabinet and anticipated installed equipment. If considering a different airflow option, discuss requirements with our team.

- AC Unit

- Heater

- Heat exchanger

- Fan assemblies

- Ducting

- Insulation

- Solar shield

Connectivity Considerations

Our outdoor cabinets are configured with cable access and electrical knockouts that accommodate the anticipated installed equipment. If considering different cable management or connectivity requirements, discuss requirements with our team.

- Equipment manufacturer requirements (i.e. length of cables, bend radius, etc.)

- Industry installation standards (i.e. Bicsi)

- Cable and conduit entry locations

- Gland plates and grommets to protect access until needed

Power Options and Considerations

- DC plant (charger)

- Inverter system

- UPS

- Input voltage: 120vac | 208vac (1-ph or 3-ph) | 240vac | 480vac| 48vdc | 125vdc

- Required system capacity

- Maximum system capacity, considering growth

- Type and quantity of input receptacles

Security Options

Our outdoor cabinets are configured with handles and access control that provide various degrees of protection. If considering a different access control, including intelligent access, discuss handle and cabinet compatibility with our team.

Integration of Accessories & Components

- Internal cable management

- Internal accessories for best practices: filler panels and brush grommet

- Bonding and grounding

- Power components: overall power solution, receptacles, battery, etc.

- Intelligent access control

- Lights

With our extensive manufacturing capabilities and the access to quality materials, AZE produces a variety of non-enclosure type products.

Our facility allow us to custom build enclosure accessories to your exact specifications like brackets, sub panels, leg kits, window kits, gland plates, drip shields, canopies/solar shields, roofs and more.

We do offer a range of value-added services that includes any thru holes, PEM installation, custom studs, welded couplings, removable eyebolts/lifting eyes, custom racks and/or unistrut installation. For enclosure finishing, powder coating is available in-house, and we have the ability to apply a dual-color! Logo or labeling options include silk-screening or engraving. Additional finishes include: passivation, electropolishing and clear anodizing for most products.

- Custom Option-Silk screening

AZE offers a full line of services on all of our enclosures to add company branding or important messages. Silk-screening, also known as screen-printing, can add color and gives your enclosures a personal touch with your company name or logo for unmistakable identification.

- Personalizes an enclosure

- Adds color

- Displays your company name or logo

- Adds value and presence

- Custom Option-ANODIZING

AZE manufactures a variety of high quality custom and standard NEMA-rated anodized aluminum enclosures. The anodizing process creates an oxide film and makes it more scratch resistant. It changes the appearance of the metal to nearly any color from red to black or even clear. Anodizing ensures your enclosure has a durable and beautiful finish. It can also provide an extra layer of corrosion resistance to aluminum enclosures.

The two most common types of anodizing include:

- Sulfuric acid anodizing, also known as Type II Anodizing, is the most widely used anodized coating solution because of its environmentally friendly composition and less expensive pricing. This film, or coating, can be dyed in any color. Hard coating anodizing, known as Type III Anodizing, is a great metal finish for aluminum. This outer coating allows the part to be protected from corrosion and deterioration.

- Hard coat anodizing enhances the properties of aluminum. It improves electrical resistance, hardness and thermal conductivity.

Common anodizing colors include; Black, Gold, Green, Blue, Red, Bronze, and Clear. Special colors available upon request.

- Other Custom Options

AZE produces a variety of NEMA enclosure type products. Our capabilities allow us to custom create products to your exact specifications and certifications to be installed anywhere in the world. A few customization options and products are:

- Cutout And Thru Holes For Mounting Hmi’S, Operator Devices And Conduit Entries

- Gland Plates On Any Or All 4 Sides Of The Enclosure - Nema,Ip, And Atex & Iecex Rated

- Welded Half Or Full Couplings

- Racks

- Enclosure Body Sunshields And Or Roofs

- Insulation With Or Without Metal Retainers – We Provide The Highest R-Value Per Inch Of Thickness

- Vast Array Of Door Closure Options For The Level Of Security You Require.

- Customized Panels Which Can Include Drilled & Tapped Holes, Pem Nuts , Studs

- Adjustable Inner Doors Or Swing Panels

- Door On Door Enclosures That Allow Hmi Access Without Opening The Main Door

- Custom Powder Coat - Single Or Dual Color Application

The outdoor enclosures are designed to protect and create a safe operating environment for industrial, telecom and broadband equipment. We know different options to our most popular size and style to make ordering and configuration even more fast, flexible, and easy! A single part number includes the cabinet and accessories that are common to NEMA applications.

AZE manufactures high quality custom and standard NEMA-rated enclosures. Contact us today to learn how we can expedite a custom enclosure and produce cost-effective NEMA-rated standard enclosures embellished with your company colors.

Buying Guides

Outdoor Enclosures Buying Guide

Outdoor enclosures are essential for protecting sensitive equipment from harsh environmental conditions. Whether you're housing networking gear, surveillance systems, or industrial controls, this guide will help you choose the right outdoor enclosure for your needs.

1. Determine Your Requirements

-

Equipment Type: Identify the equipment to be housed (e.g., servers, routers, cameras, PDUs).

-

Environment: Consider the location’s climate (e.g., extreme heat, cold, rain, or dust).

-

Space: Measure the equipment size and plan for future expansion.

2. Types of Outdoor Enclosures

-

Wall-Mount Enclosures: Attached to walls or vertical surfaces, ideal for compact setups.

-

Pole-Mount Enclosures: Mounted on poles or posts, perfect for telecommunications or surveillance systems.

-

Freestanding Enclosures: Placed on the ground or pedestals, suitable for larger equipment.

3. Key Features to Consider

-

Material:

-

Stainless Steel: Durable and corrosion-resistant for harsh environments.

-

Aluminum: Lightweight and rust-resistant.

-

Polycarbonate: Impact-resistant and ideal for lightweight applications.

-

-

IP Rating: Look for IP65 or higher for protection against dust and water.

-

Temperature Control:

-

Cooling Fans or Air Conditioners for hot climates.

-

Heaters or Thermostats for cold climates.

-

-

Security:

-

Locking doors with key or padlock options.

-

Tamper-proof designs to prevent unauthorized access.

-

-

Cable Management:

-

Cable entry points, grommets, and internal organizers.

-

-

Mounting Options:

-

Wall-mount, pole-mount, or freestanding configurations.

-

4. Size and Dimensions

-

Height, Width, and Depth: Ensure the enclosure can accommodate your equipment and allow space for airflow and cable management.

-

Internal Usable Space: Check the internal dimensions to avoid overcrowding.

5. Environmental Considerations

-

Weatherproofing: Ensure the enclosure can withstand rain, snow, and UV exposure.

-

Ventilation: Proper airflow prevents overheating and condensation.

-

Durability: Choose materials and designs that resist corrosion, impact, and vandalism.

6. Accessories and Add-Ons

-

Cooling Systems: Fans, air conditioners, or ventilation panels.

-

Heating Systems: Thermostats or heaters for cold climates.

-

Shelving and Rails: Adjustable shelves for organizing equipment.

-

Power Distribution: PDUs (Power Distribution Units) for reliable power management.

-

Lighting: Internal lighting for easier maintenance.

7. Installation and Maintenance

-

Installation: Follow the manufacturer’s guidelines for wall-mount, pole-mount, or freestanding setups.

-

Maintenance: Regularly inspect seals, clean the exterior, and ensure cooling/heating systems are functional.

8. Budget and Brand

-

Budget: Determine your budget and compare options within your price range.

-

Brand Reputation: Choose reputable brands like AZE Systems for quality and reliability.

9. Customization Options

If standard enclosures don’t meet your needs, explore custom solutions for:

-

Specific dimensions.

-

Additional cooling or heating systems.

-

Unique mounting requirements.

10. Expert Support

Consult with specialists to ensure you select the right outdoor enclosure for your application.

AZE offers a huge selection of outdoor enclosures to our customers. At the same time, we understand that it can be challenging to select the right model from such a wide variety. That's why we've assembled this brief guide to outdoor rated NEMA enclosures.

Why Choose AZE Systems?

Choosing the right outdoor rated NEMA enclosure will help keep sensitive devices safe from flying dust, pounding rainstorms and the many other kinds of environmental hazards present outdoors. So, what's the first step to ensuring that you choose the best electronics enclosure for your outdoor application? Being familiar with the many factors that will influence your selection.

AZE Systems offers high-quality outdoor enclosures designed to protect your equipment in the harshest environments. With customizable options, durable materials, and expert support, we provide solutions tailored to your needs.

Our outdoor NEMA enclosure guide presents the many options that we have available for rugged outdoor grade enclosures. With a thorough understanding of each aspect of the enclosure selection process, you'll be able to evaluate your many choices and select the right enclosure.

First up: Let's discuss how to determine the necessary qualities and features for your outdoor NEMA enclosure.

Considering Your Application

Before you investigate enclosure options, think through the qualities that your outdoor rated enclosure needs to have. An outdoor electrical junction box will have different needs from an outdoor network enclosure compared to a lockable electrical box. Consider all of these application factors when choosing an enclosure:

- The temperatures to which the device will be exposed

- The weather conditions to which the device will be exposed

- Whether the device will be subject to submersion

- Whether the device will be exposed to corrosive substances (including salt water)

- Whether the device will be exposed to flying particulates like dirt, dust and debris

- Whether the enclosure will need a hinged cover or door for easy access

- Whether the enclosure will need to be a locking electrical box

- Whether the enclosure will need a clear cover for easy instrument reading

- The amount of heat that the components in the enclosure will generate

- What kind of mounting features (such as mounting feet or PCB bosses) the enclosure will need

We'll give a brief overview of each of these factors here. We can address the weather- and environment-related factors through a relatively simple and widely used system called NEMA ratings.

What Is a NEMA Rating?

The NEMA rating scale is a critically important tool developed by the National Electrical Manufacturers Association. This scale uses numbers and letters to rate an enclosure's protective qualities against environmental hazards. NEMA ratings are the most widely used enclosure rating system in the United States. The NEMA rating system includes factors such as:

- Protection from flying particulate matter, such as dust and debris

- Protection from water, oil or coolant ingress

- Protection from corrosion

- Protection from ice formation on the enclosure

- Protection from incidental contact by employees or objects

NEMA ratings use a roughly ascending order, starting at the lowest level of protection with NEMA 1 enclosures. However, it's important to note that some numerically higher ratings are actually not the highest available. For example, NEMA 12 and NEMA 13 enclosures, despite their higher numbers, are actually lower-rated enclosures that are suitable only for indoor applications.

An enclosure with a higher NEMA rating will usually also carry the ratings below it. For example, most of our NEMA 6P enclosures also include NEMA 4X, NEMA 12 and NEMA 13 ratings. However, you should still be sure to check each enclosure's ratings thoroughly.

Which Enclosure Material Should You Choose?

Polycase offers several choices for outdoor NEMA rated enclosure materials. Each material offers its own combination of features, so the best choice depends on your intended application.

AZE offers several choices for outdoor NEMA rated enclosure materials. Each material offers its own combination of features, so the best choice depends on your intended application.

- Stainless Steel: A famously durable and attractive material created by alloying steel with other elements like molybdenum and chromium. It's pricier than other materials, but provides outstanding performance for most applications.

- Carbon Steel: Steel with a higher carbon content that's used around the world for a variety of industrial applications. It doesn't provide the same level of corrosion resistance and aesthetic excellence as stainless steel, but it's less expensive and still provides great protection.

- Aluminum: Another extremely durable and attractive metal material that offers natural radio frequency shielding. Aluminum provides great all-around performance, although it costs more and can be vulnerable to denting.

Mounting Hardware for Outdoor Rated NEMA Enclosures

Most electronics enclosures will be mounted on a surface, such as a wall or control panel. In addition, many applications require a place in the enclosure to mount internal components, such as printed circuit boards (PCBs). That means that you'll need to pay attention to the external and internal mounting hardware that's available for each model of enclosure.

- External Mounting Hardware

- Mounting feet and mounting flanges are the most common types of external mounting hardware. Mounting feet are a set of four small attachments on the exterior of an enclosure that allow it to be mounted using screws, while mounting flanges are sets of two larger pieces with the same function. Many of our enclosures offer built-in mounting feet or flanges, but we also offer screw-on mounting feet. If you need to mount your device on a utility pole, make sure to choose a pole mount kit compatible with your enclosure.

- Internal Mounting Hardware

- Many enclosures also need internal hardware to allow device components to be mounted. DIN rails and panels are two of the most common kinds of internal mounting hardware. A DIN rail is a metal rail inside an enclosure that allows for the easy mounting of equipment like circuit breakers. We offer DIN rail kits that are compatible with some of our most popular enclosures. Many Polycase enclosures offer internal mounting panels to assemble components to. The panels are then secured with screws to internal mounting bosses molded inside the enclosure's base or cover. We also offer adhesive PCB mounting standoffs for custom mounting configurations.

Heat Dissipation and Venting in Outdoor NEMA Enclosures

If the device components in your enclosure generate heat, remember that you'll have to consider heat dissipation methods. In some enclosures, passive ventilation will be enough, while others will require active ventilation measures.

First, you'll need to determine how much the heat from your components will raise the temperature inside your enclosure. Our guide to calculating heat rise in an enclosure provides an in-depth look at how to perform this critical calculation.

Determining your heat rise level will allow you to evaluate what kind of ventilation your enclosure will need. If you need active ventilation, make sure to leave room for motors, blower fans and any other forced air elements that may be required. No matter which type you use, make sure to also pick up any enclosure venting accessories that you might need.

Which color of NEMA type or IP rated Outdoor Electrical Enclosures do you need?

Outdoor Electrical Enclosures, Electrical Cabinets and Data Racks are available in a range of standard colours. Standard colours are shown below. All enclosures are supplied as RAL7035 Light Grey unless requested otherwise. Refer to tables for part number suffixes for coloured enclosures. The full range of enclosures and custom enclosures can be provided in any RAL colour upon request.

- RAL7035

- RAL9005

- RAL9016

- RAL1001

- ...etc

How to choose the best electrical enclosure to suit your need?

There are several factors to consider when choosing an electrical enclosure.

Step 1. Determine the IP Rating to suit the application

Step 2. Choose the material to suit the environment

Step 3. Select the size to suit internal components

Step 4. Add accessories including mounting brackets, ventilation and access options.

This selection guide provides information to help select electrical enclosures. Following this guide will help to optimise the life of enclosures and internal components.

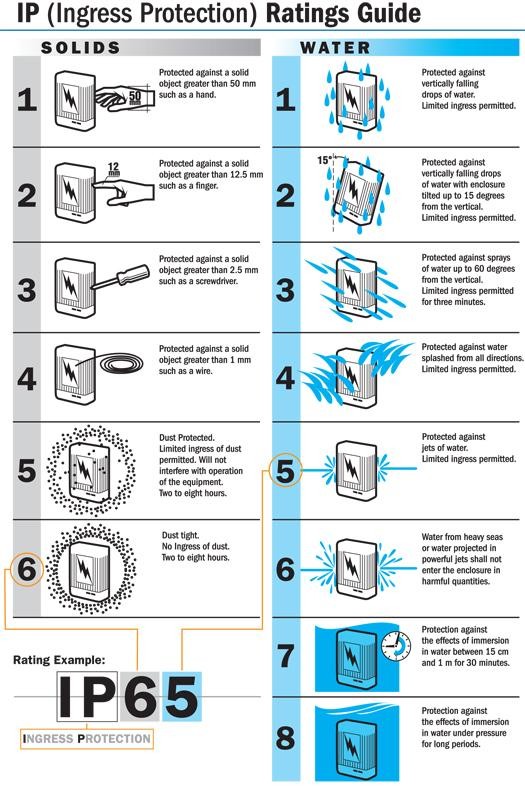

- IP Ratings

The most important decision when choosing an electrical enclosure is to select what IP rating is needed. Ingress Protection IP Ratings are defined in IEC/EN/AS60529 as a two digit code detailing the degree of protection against mechanical impact and protection against contact with live parts, ingress of solid foreign bodies and water. The degree of protection table can also be found in our electrical enclosure technical catalogue. If an outdoor or weatherproof electrical enclosure is required, it is important to select the correct enclosure with the required IP rating. Our single door electrical enclosures are IP65 while our double door electrical enclosures are IP55.

- Materials

What material is best for electrical enclosures? Material is selected based on the application, environment and location. Factors impacting selection may include strength of materials, resistance to corrosion, thermal stability, resistance to UV, mechanical impact and lifting requirements. Enclosures should be constructed of materials capable of withstanding the mechanical, electrical, thermal and environmental stresses to be encountered in service conditions. This includes protection against corrosion by use of suitable materials or by protective coatings. IP Enclosures provide powder coated galvanised steel for general industrial applications and grade 316 stainless steel for extreme duty applications that require high corrosion resistance. If the application has high levels of exposure to chemical or chemical cleaning, check for compatibility using the chemical resistance table below. Care must be taken assessing tenders and quotes offering low quality imported enclosures manufactured using low quality non-conforming stainless steel. We recommend only accepting stainless steel from high quality European mills. If in doubt, request a material test certificate from the enclosure supplier to determine country of origin of raw materials.

-

Sizes

How to size an electrical enclosure? The size of the enclosure is determined by the components and cables being housed. This includes minimum distances around components and cables. It is important to check the installation diagrams of the housed components to ensure minimum distances between and around components are maintained with regards to electrical clearances, airflow and maintenance accessibility. When sizing enclosures, the distances between a conductive barrier or enclosure and the live parts they protect should not be less than the values specified. Wall mounted steel electrical enclosures and stainless steel electrical enclosures range in size from 300H x 200W x 150D to 1200H x 1200W x 400D.

-

Mounting

How do I mount an electrical enclosure? It is important to select the best location and orientation for your enclosure. Then select a suitable mounting method to suit the overall plant layout and design of the adjacent equipment. Options include wall mounting brackets, a stand, or pole-mounting brackets. This is to provide safe access while maintaining adequate operator walkway access. In addition, if you are mounting the enclosure from an adjacent structure, it is also important to ensure the structure is adequately designed to withstand the additional loads.

-

Inner Doors

How do I attach an inner door escutcheon plate? Hinged, removable inner door escutcheons are a standard option and can be easily fitted into each enclosure for mounting components. If you require inner door escutcheons, be sure to check the depth of the enclosure to ensure minimum distances between and around components are maintained. Enclosures up to 400mm deep are available to ensure large electrical equipment and drives can be safely housed behind escutcheons.

-

Security and Locking

Locking mechanisms and hinges for doors should be of mechanical strength sufficient to withstand stresses in normal conditions and short circuit conditions. It is important to select what type of locks will be best for your enclosure. For example, a standard lock may be suitable for a small control panel inside a manufacturing facility but a special locking system may be required to restrict public access to a large outdoor weatherproof cabinet. In addition, various utilities, facilities and applications have specified lock types or key types to conform to a standard for their electrical cabinets. IP Enclosures provide standard locks with all electrical enclosures and can provide optional locking systems and swing handles to suit any requirement including electronic pushbutton and RFID locking systems. Common options are key lockable swing handles, padlockable swing handles, key lockable wing knobs and padlockable wing knobs. Keyed options are available in several barrel combinations. It is also important to consider the grade of material for locking systems and whether other more advanced interlocking systems are required.

-

Air Conditioners, Ventilation and Rain Hoods

The application, environment, location and installation may require heat deflection, venting, cooling or heating. Enclosed assemblies for outdoor and indoor installations in high humidity and temperatures varying with wide limits should be provided with suitable ventilation, heating and drain holes while protecting degree of protection. We can help you select options that you may need. Options include ventilation fans, filters, vents and sun shields. Rain hoods and vent hoods are also available. When designing the layout of the internal contents of the enclosure, allow for minimum distances around vents, filters and fans for airflow and maintenance. Electrical enclosures can be provided customised to include cut-outs with ventilation accessories fitted.

-

Electrical Safety

Can I install an electrical panel? Before starting any work, please consider electrical enclosure safety and check with your local authority for regulatory requirements. Contractors shall engage a Licensed Electrical Contractor to perform duties and functions of Electrical Works.

We design and manufacture to meet your unique needs. No matter how small, large or complex your requirements, we can work with you to provide exactly what you need. We can provide one-off prototypes and we can provide a unique product identifier so this can be made standard for high volume repeat orders. Talk to one of our representatives to see how we can help you standardise your custom enclosures today.

FAQ

FAQs: Outdoor Enclosures

1. What is an outdoor enclosure?

An outdoor enclosure is a protective cabinet designed to house and safeguard sensitive equipment (e.g., servers, networking gear, or electrical systems) in outdoor environments. It provides protection against weather, dust, vandalism, and temperature fluctuations.

2. What types of equipment can be housed in outdoor enclosures?

Outdoor enclosures are ideal for:

-

Networking equipment (e.g., routers, switches, modems)

-

Telecommunications systems

-

Power distribution units (PDUs)

-

Surveillance systems (e.g., cameras, DVRs)

-

Industrial control systems

3. What materials are outdoor enclosures made of?

Most outdoor enclosures are made from durable materials like:

-

Stainless steel: Resistant to corrosion and harsh weather.

-

Aluminum: Lightweight and rust-resistant.

-

Polycarbonate: Impact-resistant and ideal for lightweight applications.

4. What features should I look for in an outdoor enclosure?

Key features include:

-

Weatherproofing (e.g., IP65 or higher rating)

-

Temperature control (e.g., cooling fans, heaters, or air conditioners)

-

Security (e.g., locking doors, tamper-proof designs)

-

Cable management (e.g., cable entry points, grommets)

-

Mounting options (e.g., wall-mount, pole-mount, or freestanding)

5. What is an IP rating, and why is it important?

An IP (Ingress Protection) rating indicates the level of protection against dust and water. For outdoor enclosures, look for a rating of IP65 or higher to ensure protection against rain, dust, and other environmental factors.

6. How do I choose the right size outdoor enclosure?

Consider:

-

The size and quantity of equipment to be housed.

-

Space for cable management and airflow.

-

Future expansion needs.

7. Can outdoor enclosures withstand extreme temperatures?

Yes, many outdoor enclosures are designed with temperature control features like:

-

Cooling fans or air conditioners for hot climates.

-

Heaters or thermostats for cold climates.

8. Are outdoor enclosures secure?

Yes, outdoor enclosures often include:

-

Locking doors with key or padlock options.

-

Tamper-proof designs to prevent unauthorized access.

-

Reinforced construction to resist vandalism.

9. Can I customize an outdoor enclosure?

Yes, many manufacturers offer customizable options for:

-

Size and dimensions.

-

Additional cooling or heating systems.

-

Specific mounting requirements.

-

Custom cutouts for cables or ventilation.

10. How do I install an outdoor enclosure?

Installation depends on the type:

-

Wall-mount enclosures: Attached to a wall or vertical surface.

-

Pole-mount enclosures: Mounted on a pole or post.

-

Freestanding enclosures: Placed on the ground or a pedestal.

Always follow the manufacturer’s installation guidelines.

11. How do I maintain an outdoor enclosure?

-

Regularly inspect for damage or wear.

-

Clean the exterior to remove dirt and debris.

-

Check seals and gaskets for proper weatherproofing.

-

Ensure cooling or heating systems are functioning correctly.

12. Can outdoor enclosures be used indoors?

Yes, outdoor enclosures can be used indoors, especially in environments requiring high levels of protection (e.g., dusty or humid areas).

13. What is the lifespan of an outdoor enclosure?

With proper maintenance, outdoor enclosures can last 8-10 years or more, depending on the material and environmental conditions.

14. Where can I buy outdoor enclosures?

Outdoor enclosures are available from manufacturers like AZE Systems, industrial suppliers, or online retailers.

15. Do outdoor enclosures come with warranties?

Most reputable manufacturers offer warranties, typically ranging from 1 to 5 years, depending on the product and brand.

What is an IP Rating?

Protect your electrical enclosure and its contents by knowing where and how it will be used so that you can order one with the correct IP Rating.

An IP (Ingress Protection) rating is used by buyers in Europe to specify the extent of protection an electrical enclosure has against environmental conditions.

The IP rating system was established by the International Electromechanical Commission (IEC), a worldwide organization for standardization. The object of the IEC is to promote International cooperation on all questions concerning standardization in the electrical and electronic fields. The IEC collaborates closely with the International Organization for Standards (ISO).

AZE strictly adhere to the International Electrotechnical Commission standardized international (or Ingress) Protection Code, which defines an enclosure's rating. The IP Code reflects the degree of protection as "IP" followed by two numbers. The first digit ranges from 0 to 6, reflecting in degrees the level of protection against particles, and protection to others from enclosed hazards. The second digit ranges from 0 to 8 and indicates the extent of protection against water.

- What is IP54 Enclosure?

An enclosure's IP followed by two numbers; the first digit shows the extent to which equipment is protected against particles, and the second digit indicates the extent of protection against water. Our IP54 enclosures have a high level of protection against particles, and a fair amount of protection against water.It has characteristics:

- Protection from dirt, dust, oil, and other non-corrosive material

- Protection from contact with enclosed equipment

- Protection from splashing water

- Available in aluminum, carbon steel, and stainless steel

- Available in wall-mounted, free standing, troughs, and JIC box

- Engraving, silk-screening, or anodizing services available

- Custom with cutouts, insulation, hinges, latches or locks

- What is IP55 Enclosure?

The IP Code reflects the degree of protection as "IP" followed by two numbers; the first digit shows the extent to which enclosures are protected against particles, and protection to others from enclosed hazards. The second digit indicates the extent of protection against water. We carry IP55 enclosures that demonstrate almost complete protection from particles and a good level of protection against water.It has characteristics:

- Protection from dirt, dust, oil, and other non-corrosive material

- Complete protection from contact with enclosed equipment

- Protection from water, up to water projected by a nozzle against enclosure from any direction

- Available in aluminum, carbon steel, and stainless steel

- Available in wall-mounted, free standing, trough, and JIC box

- Engraving, silk-screening, or anodizing services available

- Custom with cutouts, insulation, hinges, latches, or locks

- What is IP65 Enclosure?

The IP Code reflects the degree of protection as "IP" followed by two numbers; the first digit shows the extent to which enclosures are protected against particles, and protection to others from enclosed hazards. The second digit indicates the extent of protection against water. We carry IP65 enclosures which offer complete protection against particles, and a good level of protection against water.

- Complete protection from dust, oil, and other non-corrosive material

- Complete protection from contact with enclosed equipment

- Protection from water, up to water projected by a nozzle against enclosure from any direction

- Silk-screening, anodizing, or engraving services available

- Custom with cutouts, insulation, hinges, latches or locks

What is the NEMA Ratings for Enclosures

The National Electrical Manufacturer Association (NEMA) uses a standard rating system that defines the types of environments in which an electrical enclosure can be used, and frequently signifies a fixed enclosure's ability to withstand certain environmental conditions. It is NEMA's belief that utilizing standards benefits the user as well as the manufacturer. It improves safety, economics and communication between manufacturer and purchaser. A standard of NEMA defines a product in reference to its attributes and capabilities. We produce quality enclosures in a variety of materials, types and NEMA ratings.

| Type of Enclosure | ||||||||||

| Provides a Degree of Protection Against the Following Conditions | 3 | 3X | 3R* | 3RX* | 3S | 3SX | 4 | 4X | 6 | 6P |

| Access to hazardous parts | X | X | X | X | X | X | X | X | X | X |

| Ingress of solid foreign objects (falling dirt) | X | X | X | X | X | X | X | X | X | X |

| Ingress of water (Dripping and light splashing) | X | X | X | X | X | X | X | X | X | X |

| Ingress of water (Rain, snow, and sleet **) | X | X | X | X | X | X | X | X | X | X |

| Sleet ** | … | … | … | … | X | X | … | … | … | … |

| Ingress of solid foreign objects (Windblown dust, lint, fibers, and flyings) | X | X | … | … | X | X | X | X | X | X |

| Ingress of water (Hosedown and splashing water) | … | … | … | … | … | … | X | X | X | X |

| Corrosive agents | … | X | … | X | … | X | … | X | … | X |

| Ingress of water (Occasional temporary submersion) | … | … | … | … | … | … | … | … | X | X |

| Ingress of water (Occasional prolonged submersion) | … | … | … | … | … | … | … | … | … | X |

* These enclosures may be ventilated.

** These fibers and flyings are nonhazardous materials and are not considered Class III type ignitable fibers or combustible flyings.

- What are NEMA12 ENCLOSURES

AZE produces NEMA 12 enclosures which are intended mainly for indoor industrial, manufacturing, and machining applications. These metal enclosures will protect against dust, dirt, and dripping non-corrosive liquids, oil and lubricants. Our adherence to NEMA standards will give you a quality enclosure for any industrial application. We produce a number of enclosure types in aluminum, carbon steel and stainless steel delivered quickly at competitive prices. The NEMA12 enclosures have Characteristics:

- Primarily for industrial indoor use

- Protection against dust, falling dirt, fibers and lint

- Protection from dripping water and other noncorrosive liquids

- Resistant to damage from external condensation of noncorrosive liquids

- Doors with oil-resistant gaskets

- Available with pre-punched holes, cutouts, lift-off hinges, insulation, latches or locks

- What are NEMA 3R ENCLOSURES

AZE manufactures NEMA 3R enclosures for housing power distribution, lighting contractors, switch gear, and other electrical components that need to be protected in an outdoor environment,it will give you a quality weatherproof enclosure resistant to rain, ice, and snow. NEMA 3R enclosures are compatible for both indoor or outdoor applications and holds the least demanding rating for outdoor use. We produce top quality metal enclosures in a variety of types and materials, all at competitive prices; quick delivery is our specialty. The NEMA 3R enclosures have Characteristics:

- Protection against incidental contact with enclosed equipment

- Protection from falling dirt, rain, sleet and/or snow

- Drainage provision

- Protection against rain at a level higher than the lowest live part

- Alternate locking and latching mechanisms available

- What are NEMA 4 ENCLOSURES

NEMA 4 enclosures are intended mainly for outdoor use where extra protection against moisture and wind driven rain is required. Our NEMA 4 enclosures come in powder coated carbon steel and are available in a variety of types, such as wall-mounted, free-standing and JIC.The NEMA 4 enclosures have Characteristics:

- Indoor or outdoor applications

- Protection against windblown dust and rain

- Protection of electrical components from splashing and hose-directed water

- Ice forming damage protection

- Custom pre-punched holes, cutouts, lift-off hinges, insulation, latches or locks available

- What are NEMA 4X ENCLOSURES

NEMA 4X enclosures are primarily intended for outdoor use and offer a superior level of protection from corrosion and extreme environments.The NEMA 4X Enclosures have material options:

- 5052-H32 aluminum,

- 304/304L stainless steel

- 316/316L stainless steel

NEMA 4X Enclosures are available in a number of styles for your demanding applications. Our adherence to the rigorous NEMA standards will give you a quality enclosure, delivered quickly at a competitive price. The NEMA 4X enclosures have Characteristics:

- Indoor or outdoor use, including offshore applications

- Protection against windblown dust and rain

- Protection from splashing water and hose-directed water

- Corrosion-resistant

- Available with pre-punched holes, insulation retainers, welded couplings and view windows

AZE manufactures quality custom and standard NEMA-rated enclosures. Custom powder coating and silk-screening is available. Contact us today to learn how we can expedite a custom enclosure and produce cost-effective standard NEMA-rated enclosures to protect your equipment.

Related Article

Get A Quote

How It Works:

1.Submit your project details

2.Our engineers review specs & volume

3.Receive a no-obligation quote (with prototype options if eligible)

Prototype availability depends on:

• Project complexity • Order quantity • Technical feasibility

Why AZE?

✓ 100+ Custom Solutions Delivered

✓ 48-Hour Quote Guarantee

✓ End-to-End Support